Product introduction

Capacitive reactance reactive power compensation components are composed of power capacitors and filter reactors. A compensation circuit is formed by connecting capacitors and reactors in series, which plays the role of reactive power compensation and suppressing harmonics of a specific frequency, forming relatively independent compensation and detuning functions. the switching unit. Mainly used in power frequency 50/60Hz AC power system to compensate the inductive reactive power of power frequency power system to improve power factor, improve power supply quality and reduce line loss.

Features

1. The capacitors are synchronized with those of Europe, adopting a one-time forming cylindrical aluminum alloy shell, which has the characteristics of good heat dissipation, light weight and small volume.

2. The capacitors are dried under high vacuum and injected with protective gas by high-tech methods.

3. Capacitor products are specially designed and manufactured with extremely low impedance and heat loss.

4. The capacitor adopts high-quality high-temperature resistant film as the medium, which has low loss, long life and strong inrush resistance.

5. The capacitor adopts double safety protection: secondary protection device and pressure cut-off protection device, reaching 100% explosion-proof function, and it will appear as an open circuit when it fails.

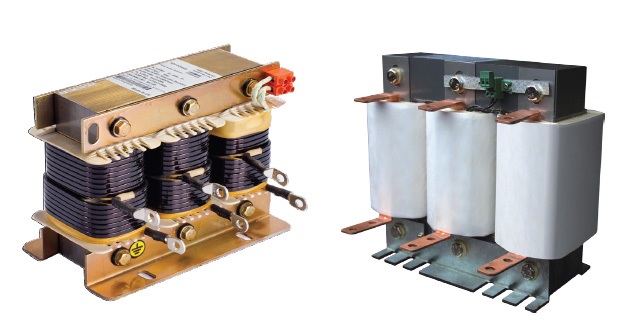

6. Reactors are divided into three-phase and single-phase, both of which are iron core dry type.

7. The iron core of the reactor is made of imported cold-rolled E-type silicon steel sheet with high quality and low loss. The core column is divided into uniform small sections by multiple air gaps. does not change in.

8. The coil of the reactor is made of grade H or grade C enameled wire, which is closely arranged and evenly arranged. The outer surface is not covered with an insulating layer, which has excellent aesthetics and good heat dissipation performance.

9. After the coil and iron core of the reactor are assembled into one body, they go through the process of pre-bakingŌåÆvacuum dippingŌåÆheat-baking and curing, using H-level dipping varnish to firmly combine the coil and iron core of the reactor, not only The noise during operation is greatly reduced, and it has a very high heat resistance level, which ensures that the reactor can safely operate without noise at high temperatures.

10. The fasteners of the reactor core column are made of non-magnetic materials to ensure that the reactor has a high quality factor and a low temperature rise, ensuring a better filtering effect.